Using recycled materials to create new products. It seems like such an obvious answer to the overconsumption of natural resources and huge quantities of waste produced. So what is holding businesses back from fully embracing recycled materials?

As a furniture manufacturer with a rich history of utilizing recycled materials, we explore the mutual advantages for us and our customers in making furniture from recycled materials. However, these benefits extend beyond furniture to other products too.

The Benefits:

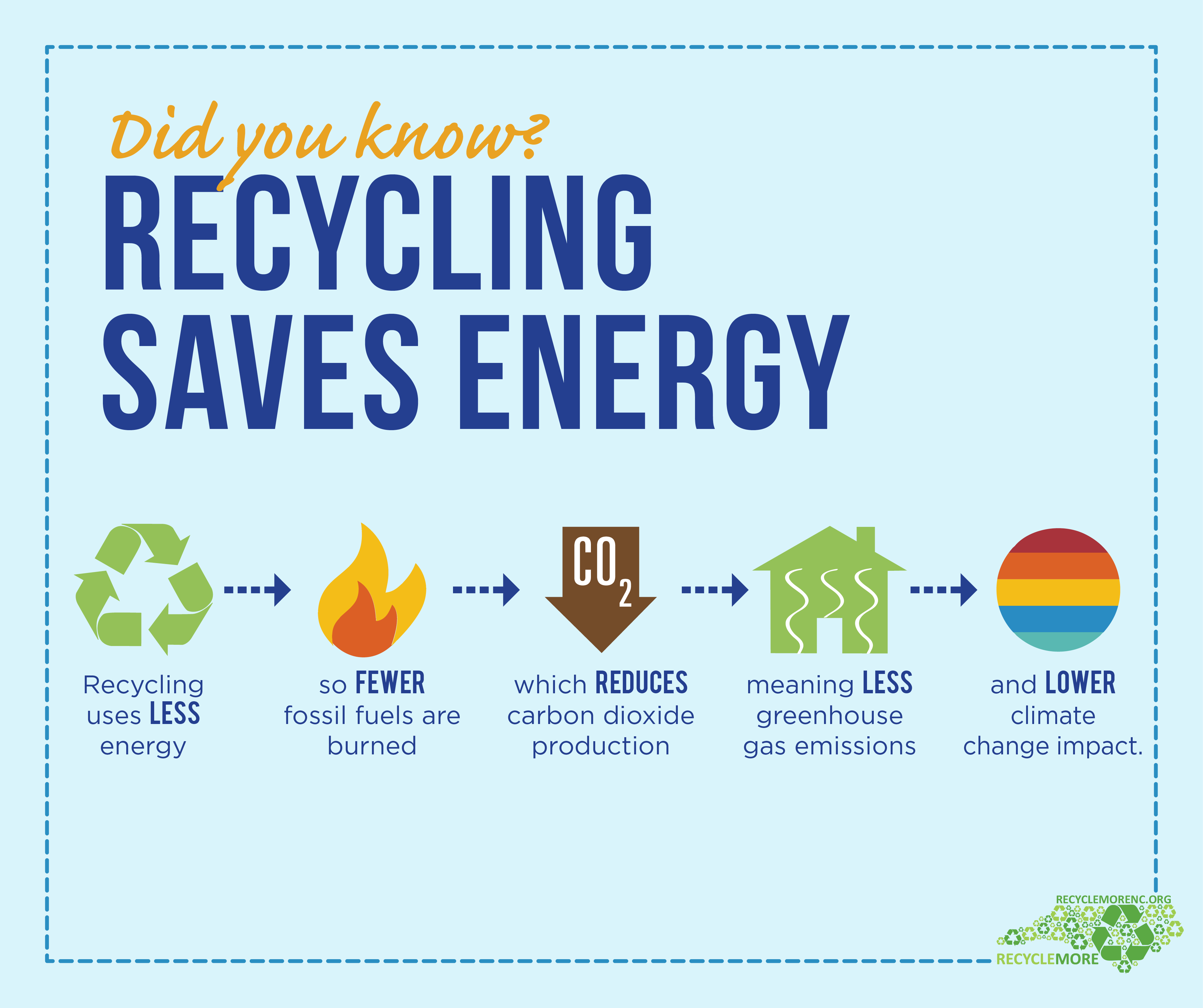

IT SAVES ENERGY

Producing products from recycled materials consumes significantly less energy compared to manufacturing them from raw materials. This is because recycled materials have already undergone refining and processing once, which is both energy and resource-intensive.

Molded recycled aluminum requires 95% less energy to produce than virgin aluminum, a material that can be recycled endlessly. In the case of steel, that percentage is approximately 70%. Moreover, paper made from pulped recycled paper consumes 40% less energy than paper made from virgin wood fibers.

Looking at the three most recyclable plastic varieties - Polyethylene (PET), High Density Polyethylene (HDPE) and Polypropylene (PP) - the expended energies to produce virgin plastics are X1.7, X3.0 and X3.0 times greater respectively when compared to using post-consumer recycled plastic pellets. A figure which also includes the collection and sorting of waste plastics and the production of sorted recycled plastic pellets.

IT REDUCES CARBON EMISSIONS AND POLLUTION

The ripple effect of less energy-intensive production includes a reduction in carbon emissions and pollutants. Using the same three plastic varieties as an example, the decrease in emissions to create recycled resin versus virgin resin is 67% for PET, 71% for HDPE, and 71% for PP. According to a comprehensive study conducted by the Association of Plastic Recyclers (APR), only four out of a total of 84 examined categories did not demonstrate savings.

When considering metals, recycled steel production as opposed to virgin steel reduces air pollution by 86%, water use by 40%, and water pollution by 76%. Furthermore, producing recycled molded aluminum decreases Co2 emissions by 92% compared to raw aluminum.

Waste plastic is first shredded, at specialty processing factories before being molded into pellets.

IT CONSERVES NATURAL RESOURCES

Using recycled materials conserves natural resources that are not infinite. Earth Overshoot Day, which calculates the date each year when humanity begins to extract more resources than the planet can realistically replenish, currently falls on July 25th (as of 2024) - a date that has steadily moved earlier in the year since its inception in 1970. As an alarming reference point, in 1990, Earth Overshoot Day was as late as October 11th.

With a market value of $527billion, the furniture industry consumes a significant amount of materials. Utilizing as much recycled content as possible, particularly plastic and metal, is a vital method businesses can employ to reduce the global reliance on virgin materials.

IT HELPS TO PROTECT WILDLIFE AND NATURE

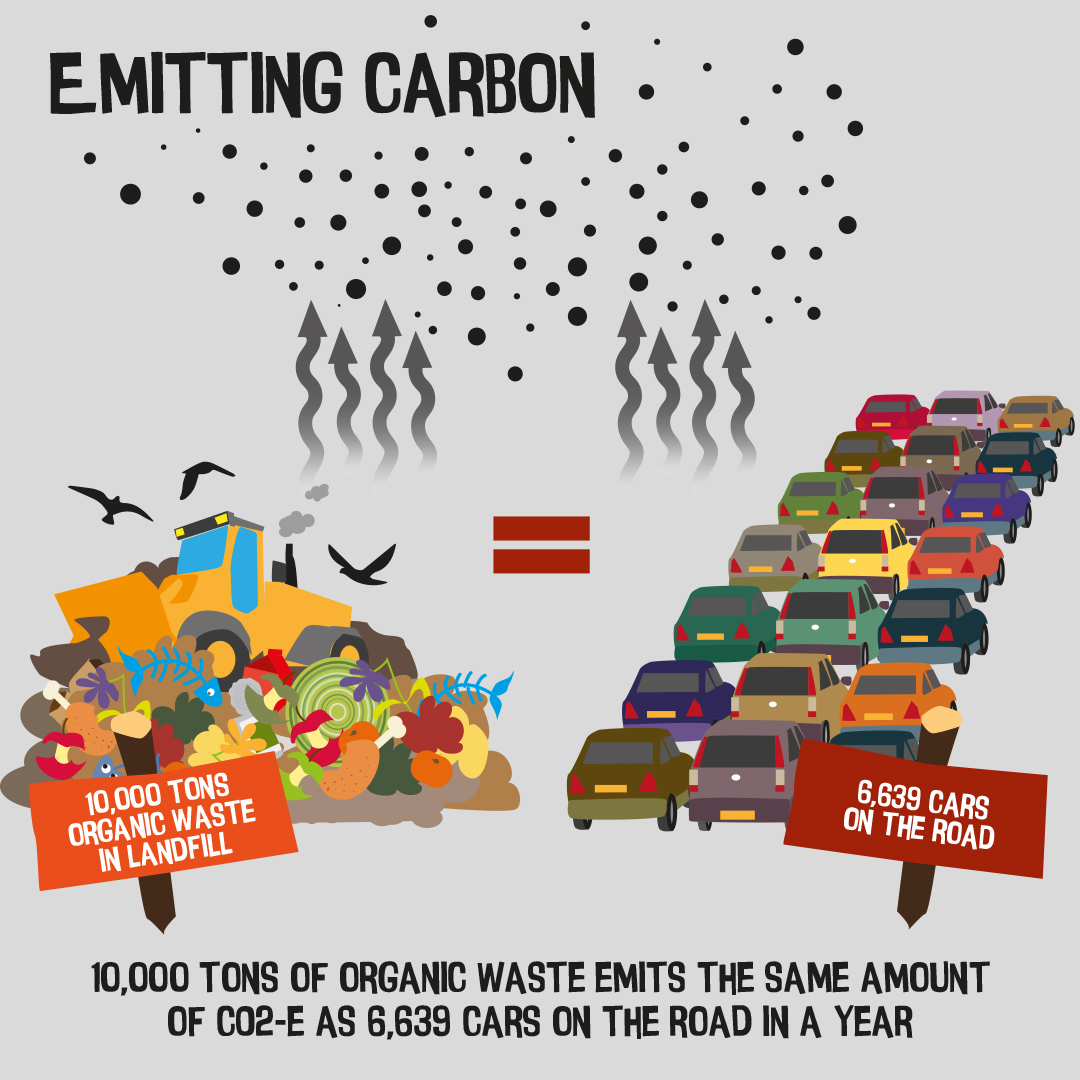

Recycling materials reduces the amount of waste that is either incinerated, deposited in landfills, or dumped in natural habitats or waterways. Less than 20% of municipal waste is recycled each year, with significant quantities ending up in landfills. It is estimated that by 2050, worldwide municipal solid waste generation will have increased by roughly 70% to reach 3.4 billion metric tons.

Furthermore, recycling rates actually declined across Europe, Asia, and the US due to the COVID-19 pandemic. Additionally, the pandemic led to a surplus of new waste in the form of personal protective equipment (PPE) and single-use items. Research published in the Proceedings of the National Academy of Sciences revealed that the pandemic resulted in over 8 million tons of plastic waste globally, with more than 25,000 tons of that waste entering the ocean.